Tanks are essential components in pharmaceutical manufacturing, used for storing, mixing, holding, and sometimes processing liquids or semi-solids at various stages of drug production.

When you are ready, please select the “Request For Quote” above to have the leading Pharmaceutical Equipment Manufactures meet your needs.

Here’s how they are employed:

-

Storage:

Raw Materials: Tanks store bulk liquids like solvents, water for injection (WFI), purified water, or liquid APIs before they are used in production.

Intermediates: Hold products at different stages of manufacturing, ensuring availability for subsequent steps.

Finished Products: Used for holding final liquid formulations before packaging or further processing.

-

Mixing and Blending:

Solution Preparation: Tanks with agitation systems (e.g., stirrers, impellers) are used to mix APIs with solvents or excipients to create solutions or suspensions for oral or injectable formulations.

Emulsion Formation: Specialized tanks with high-shear mixers can create stable emulsions for topical products like creams or lotions.

-

Processing:

Reaction Vessels: Some tanks serve as reactors where chemical reactions occur under controlled conditions (temperature, pressure, agitation) to synthesize or modify APIs.

Filtration: Tanks can be part of a filtration setup, holding material before or after filtration to remove particulates or clarify solutions.

Heat Treatment: Used in processes like pasteurization or sterilization where liquids are heated to specific temperatures for a set time.

-

Holding and Buffering:

Process Buffering: Tanks act as buffers in continuous manufacturing, holding materials between process steps to ensure a steady supply without interruptions.

Cleaning Solutions: Hold cleaning agents used in Clean-in-Place (CIP) systems for equipment sanitation.

Types of Tanks Used:

Stainless Steel Tanks: Predominant due to their durability, corrosion resistance, and ease of cleaning. They are used in various configurations:

-

Mixing Tanks: With internal baffles and agitators for homogeneous mixing.

-

Pressure Vessels: For processes requiring pressure control.

-

Jacketed Tanks: Have an outer jacket for heating or cooling the contents via steam or chilled water.

Glass-Lined Tanks: For chemical resistance when dealing with corrosive substances.

Plastic Tanks: For less aggressive chemicals or when cost is a significant factor, though less common due to concerns about leaching and durability.

Single-Use Tanks: Increasingly used for biopharmaceuticals to reduce cleaning validation, cross-contamination risks, and improve flexibility.

Operational Features:

Agitation: Various types like paddle, anchor, or high-shear mixers for different mixing needs.

Temperature Control: Heating or cooling jackets, coils, or external systems to manage process temperatures.

Level Monitoring: Sensors to maintain inventory control and prevent overflow or underfill.

Sterility and Cleanliness: Designed for easy cleaning, often with smooth surfaces and no dead spaces where contaminants could reside.

Regulatory and GMP Compliance:

Validation: Tanks must be validated for cleaning, sterilization, and performance to ensure they do not affect product quality.

Documentation: Records of tank usage, cleaning, maintenance, and validation are crucial for regulatory audits.

Material Compatibility: The tank materials must be non-reactive with the pharmaceutical products they hold.

Benefits:

Process Control: Tanks allow for precise control over conditions like temperature, pH, and mixing, crucial for product consistency.

Scalability: From small lab-scale tanks to large industrial vessels, they accommodate different production scales.

Versatility: Can be used for a wide range of processes from simple storage to complex reactions or formulation.

Challenges:

Cleanability: Ensuring tanks are thoroughly cleaned between batches to prevent cross-contamination, especially in multi-product facilities.

Maintenance: Regular maintenance is necessary to prevent corrosion, wear, or mechanical failures.

Tanks in pharmaceutical manufacturing are versatile containers used for storing, processing, and mixing materials. They are designed to meet the stringent requirements of pharmaceutical production, ensuring product quality, safety, and compliance with regulatory standards.

Leading Plastic Tanks Manufacturers

Roto Dynamics Inc. open_in_new

Location: Orange, CA

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry. We produce quality products at competitive prices. A turnkey manufacturing experience is offered where you will receive assistance with concept sketches, design, engineering, prototyping, manufacturing, quality assurance and logistics.

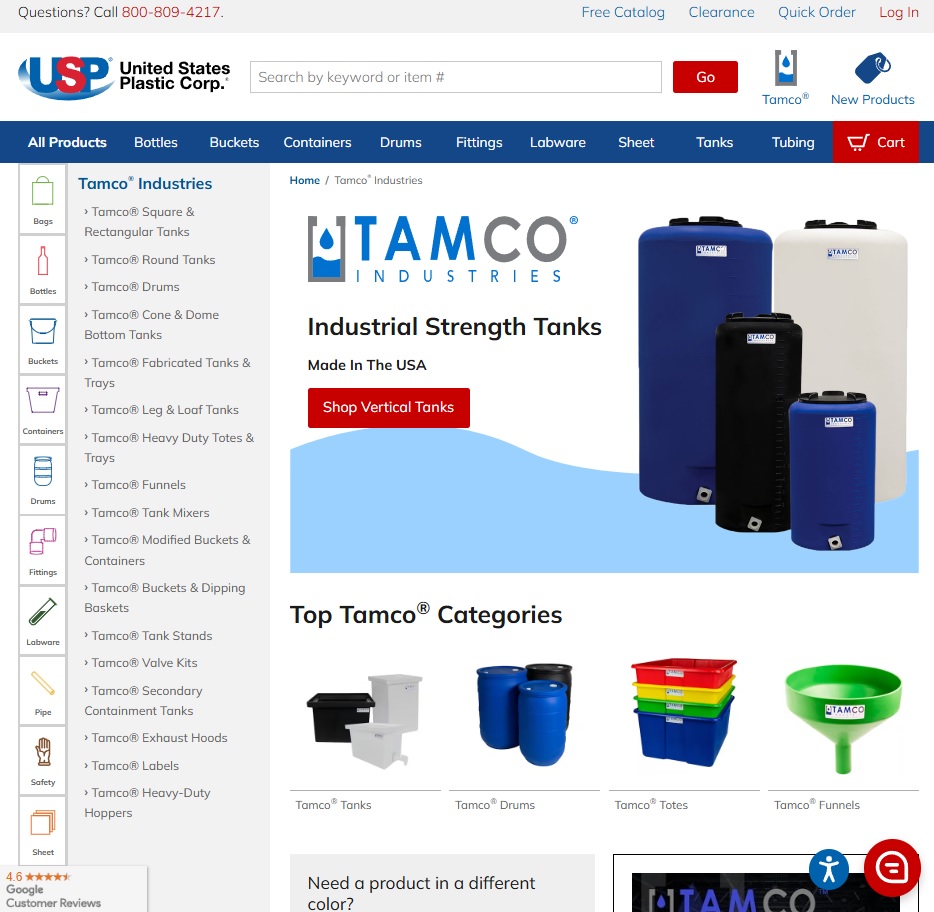

U.S. Plastic Corp. open_in_new

Location: Lima, OH

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

Sherman Roto Tank open_in_new

Location: Pearland, TX

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

All Plastics and Fiberglass, Inc. open_in_new

Location: Mobile, AL

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs. No matter how large or small the job is, we are committed to a process that assures our valued customers of the highest quality plastic tanks available on the market. Our quality control gives you the best product as well as a product that will last.

Wagner Enterprise, Inc. open_in_new

Location: Troy, MI

Wagner Enterprise is a trusted leader in designing and manufacturing industrial tanks and mixers, providing reliable solutions for a wide range of industries. With a focus on innovation, quality, and customer satisfaction, we specialize in delivering custom-engineered tanks and mixers that meet the unique needs of our clients.

Ryan Herco Flow Solutions open_in_new

Location: Burbank, CA

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Plastic Tanks and storage containers, tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, instrumentation, flowmeters, sensors and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.